Experimenting with Gigabot for printing furniture in a DIT approach

INEDIT stands for the development of new forms of design and innovative production of the furniture in the next short future. The Université de Lorraine (UL) is seeking for making feasible the idea of printing objects from recycled plastics for the personalized furniture.

But first, some technical aspects need to be tackled. One of the initial elements is to guarantee the printability using only virgin materials. Starting from this, we can imagine experimenting with recycled assets. Hence, from the months of March 2021 to June 2021, UL researchers and Master 2 students made many tests at the Lorraine Fab Living Lab®, the UL innovation space, with our prototype of Gigabot X, the first model in Europe.

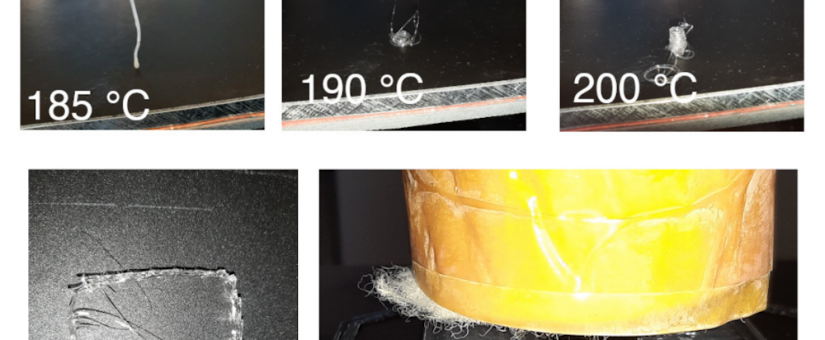

As all technologies, many parameters influence the quality; and 3D printing is not an exception. For instance, to validate the printability, one of the initial tests is related to the influence of the temperature in the process.

One major difference with the traditional Fused Filament Fabrication is that the flow of material is controlled by the pression that the rollers have on the filament to enter in the hot chamber, and then, to the nozzle. In the Fused Granular Fabrication (as Gigabot), this pressure is controlled by the rotation of the screw. Thus, the frictional and the temperature variables interact each other to melt material. While controlling the friction is a little bit complicated, we initially tested the impact of the temperature variation on the flow of the traditional Polylactic Acid (PLA). Material widely used in the 3D printing world.

We expect to identify the key variables that we need to consider for obtaining high quality parts for furniture. Ideally, this will be the basis to describe the ‘perfect’ operating conditions given a plastic material. Hence, we started to explore some printed objects as benchmarking tests to quickly inspect the final product. Certainly, this is the first elements that will give us the basis to build robust process for INEDIT EU project.

In the following months, we will continue to explore the print quality using virgin and recycled assets. This will be a milestone for INEDIT in order to assure that plastics waste could be an important material for the future of furniture.